When printing on dark shirt colors, you need a base plate of white.

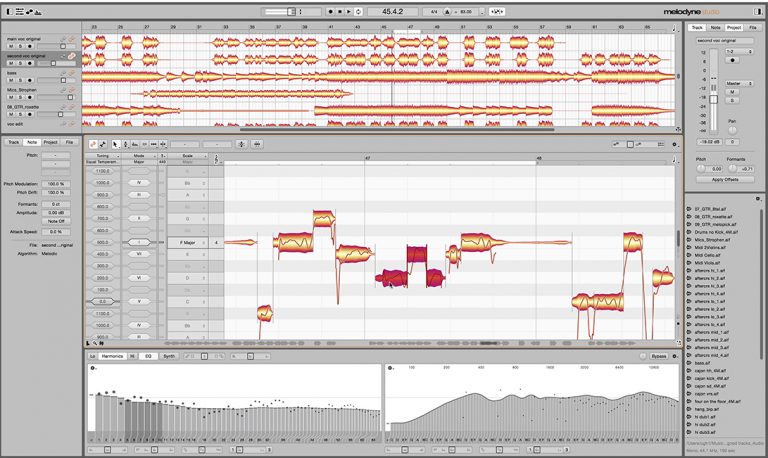

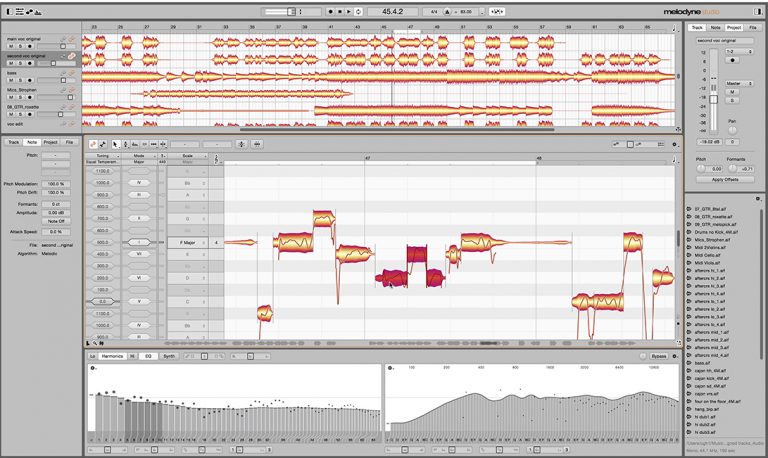

Choke underbases for better registration. When scanning lineart, scan at resolutions of 800 to 1200 dpi in order to have your tracing program like Streamline or Corel Trace, give you a much more accurate bitmap to vector conversion of the image. Make your own custom targets and assign them a color of “Registration Color” that means they will print on each separation. The “stock” registration targets in all programs are generally too small and you don’t have any control over their placement. You need to allow for this by using a lower percentage tint in shading areas so when it is printed it will look correct. When you print a halftone dot, it will grow in size 30% to 50%. If using halftone dots or tints of color in an image, when output, these areas are made up of small dots called halftones. A trap is generally done by adding an outline/stroke to undercolors to make them slightly fatter (figure 1). If you spend time adding traps, images will appear to be in register when they are not. A trap can be as small as 2 points for shops that can hold tight registration, or as big as 6 points for simple images on low-end equipment. Trapping is the overlapping of darker colors (like black) ontop of undercolors. If your “films” are output on a laser printer, they many not line up. When printing spot colors, any out of registration will show up as gaps between colors. The funny thing about printing shirts is that sometimes spot color images where colors touch colors are often HARDER to print than photorealistic images made up of halftone dots. Vector based programs like Corel Draw, Adobe Illustrator and Macromedia Freehand are generally used for spot color images or images with a hard edge and more of a cartoon look.

Others are just good nuts-and-bolts suggestions that can make or break a set of seps. In order to fit this in the allotted space, many tips are brief suggestions that will may require referring back to your software manual to figure out. This article lists 25 tips for better separations. – but it all starts with color separations. Yes, yes, you need to use properly tensioned screens, good press setup, proper ink viscosity, etc. As you become a better printer, it doesn’t take long to learn that in most cases if the separations are done correctly, the print looks great. Over the years I have learned that one of the major secrets to good printing is good color separations. 5 Things to Consider When Choosing a Custom Screenprinter.

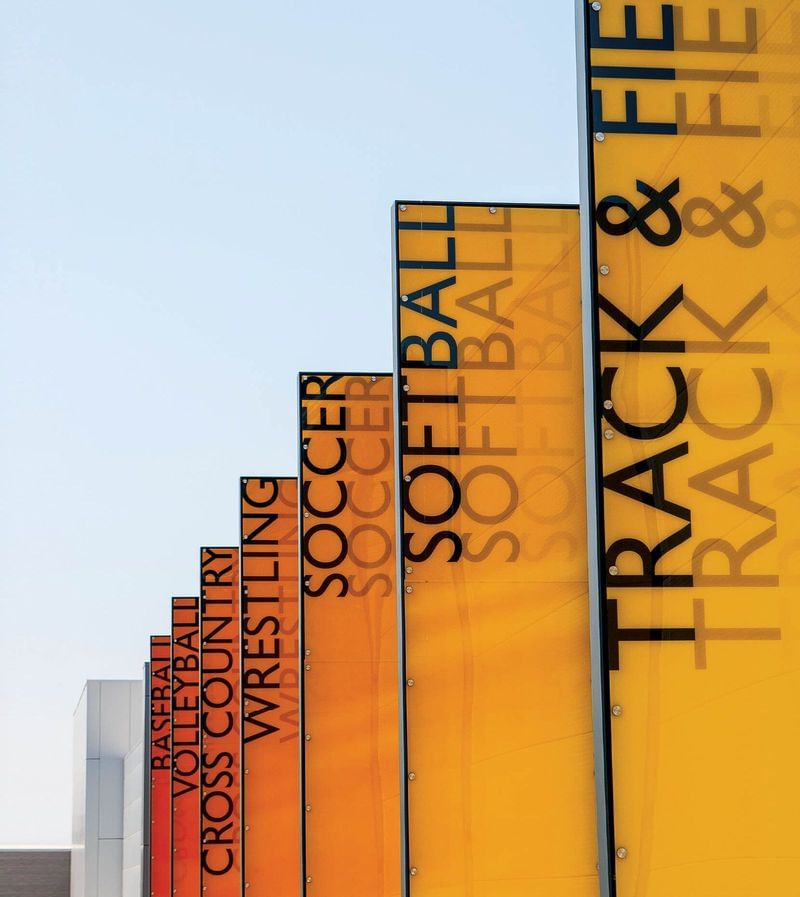

Custom Expert Brand Cross-Fit & Yoga Apparel. 2 Things You Need to Know About Bandanas. Covid-19: Bandanas Not Just for Fashion Anymore.

0 kommentar(er)

0 kommentar(er)